Your strategic partner

in ultra-high precision manufacturing

0,2 µm

MAX RESOLUTION

< 2 µm

TOLERANCE

<0,1 µm

Ra SURFACE ROUGHNESS

An expert will reply within 24 hours

At the forefront of resolution to redefine what's possible

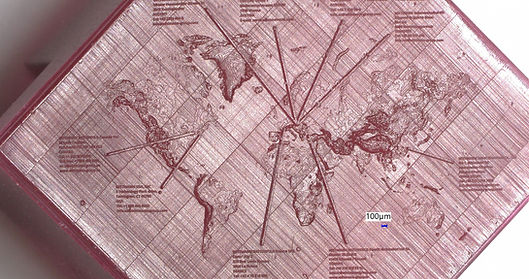

NanoVoxel provides a unique service to support customers in the realization of ultra-high precision components that would have been nearly impossible to produce otherwise. By pushing the boundaries of what’s physically possible, we deliver the next-generation microparts.

)%20(1)_edited.png)

Don't limit yourself to just one technology

Our micromanufacturing approach allows you to strategically combine different techniques, maximizing speed, precision, and material versatility. We enable rapid prototyping achieving resolutions down to 0.2 microns.

The strategy with no compromises

We address the different stages of the production process. In this context, we adapt both budget and materials, transitioning from ultra-resolution photoresins to ceramics, TPE, glass, and epoxies, while appropriately modifying production procedures to ensure the highest quality and performance of the final product.

Our in-house technologies

2PP 3D PRINTING

Two-photon polymerization (2PP) 3D printing overcomes the limitations of traditional micro injection molding and micromachining, which are costly, time-consuming, and inflexible for low-volume production. Our advanced 2PP printers achieve micro- and nanometer-scale precision (up to 0.2 µm), ensuring cost efficiency, fast delivery, and a competitive edge in prototyping. This additive manufacturing method also enables the creation of complex structures that would be challenging with conventional techniques, allowing for rapid design modifications.

MICRO-INJECTION MOLDING AND CASTING

Micro-injection molding gives numerous benefits for large volume mass production.

Having amassed three decades of proficiency in micro injection molding, we have fine-tuned the process, allowing us to fabricate substantial quantities of microparts in a cost-effective manner, with unparalleled delivery speed. Depending on your specifications, we leverage geometries and materials to increase the functionality and efficiency.

MICRO-ASSEMBLY & ENGINEERING CONSULTING

In addition to our manufacturing services, we provide comprehensive support in the planning and conception of micro-components. Our team of experts assists in optimizing the design of micro parts to enhance their efficacy, determines the most fitting production method, and suggests recommendations for improvement.Furthermore, we offer cost-effective micromanipulation tools for further processing in addition to the fabrication of microcomponents.

Unmatched features

to enhance

your performance

Our technology offers the following exceptional characteristics:

-

Resolution down to 0.2 µm, enabling the most precise and detailed outputs.

-

Average tolerances below 5 µm, ensuring consistent accuracy across all components.

-

Surface roughness down to 100 nm, achieving an ultra-smooth finish ideal for high-quality results and enhanced performance.