Powered by the sharpest resolution in the industry

Nanovoxel is your all-in-one contract manufacturer, capable of adapting strategies to materials, costs, and required micro features. Through a seamless combination of ultra-high-resolution 3D printing, micro-injection molding, casting, and other technologies, we deliver tailored microparts that meet the precise demands of your projects.

)%20(1)_edited.png)

From slowdowns and limitations,

to rapid ultra-precise prototyping

Before NanoVoxel

Design limitations

One manufacturing process

Extended lead time

After NanoVoxel

Possibility to design 3D intricated structures

Multiple in-house manufacturing technologies

2-week average lead time

Our in-house technologies

2PP 3D PRINTING

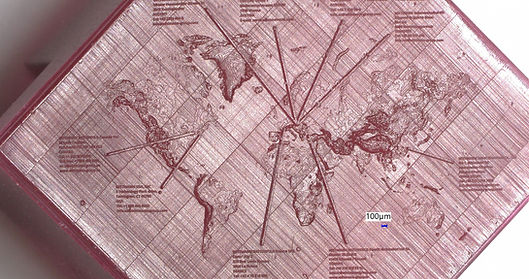

Two-photon polymerization (2PP) 3D printing overcomes the limitations of traditional micro injection molding and micromachining, which are costly, time-consuming, and inflexible for low-volume production. Our advanced 2PP printers achieve micro- and nanometer-scale precision (up to 0.2 µm), ensuring cost efficiency, fast delivery, and a competitive edge in prototyping. This additive manufacturing method also enables the creation of complex structures that would be challenging with conventional techniques, allowing for rapid design modifications.

MICRO-INJECTION MOLDING AND CASTING

Micro-injection molding gives numerous benefits for large volume mass production.

Having amassed three decades of proficiency in micro injection molding, we have fine-tuned the process, allowing us to fabricate substantial quantities of microparts in a cost-effective manner, with unparalleled delivery speed. Depending on your specifications, we leverage geometries and materials to increase the functionality and efficiency.

MICRO-ASSEMBLY & ENGINEERING CONSULTING

In addition to our manufacturing services, we provide comprehensive support in the planning and conception of micro-components. Our team of experts assists in optimizing the design of micro parts to enhance their efficacy, determines the most fitting production method, and suggests recommendations for improvement.Furthermore, we offer cost-effective micromanipulation tools for further processing in addition to the fabrication of microcomponents.

Unmatched features

to enhance

your performance

Our technology offers the following exceptional characteristics:

-

Resolution down to 0.2 µm, enabling the most precise and detailed outputs.

-

Average tolerances below 5 µm, ensuring consistent accuracy across all components.

-

Surface roughness down to 100 nm, achieving an ultra-smooth finish ideal for high-quality results and enhanced performance.

In the need of consistency?

We measure your microparts.

Accurately measuring micro-sized parts poses a significant challenge. However, we possesses the requisite expertise and cutting-edge technology to provide precise and dependable dimensional analysis of your components. Our capabilities encompass an extensive range of advanced techniques such as nano-precision laser 3D profilometry, SEM microscopy, and micro-computer tomography.

Overcome your challenges.

Talk with us.