top of page

What industry do you belong to?

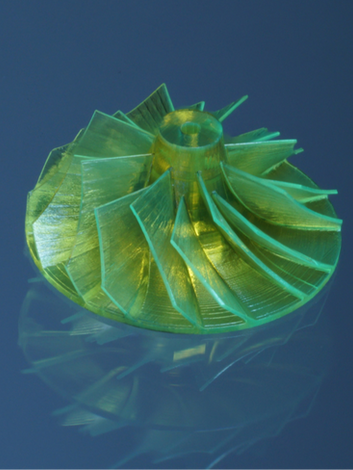

We can work on projects and industries that demand extremely high resolution,

overcoming traditional development challenges.

Services

How we work

We value your needs, and put techinical experts at your disposal.

CUSTOMER REQUEST

We receive the client's request and possible drawings.

DEDICATED MEETINGS

We assess feasibility, and offer customised suggestions.

CAD WORK & PRODUCTION

We select the process best suited to the client's needs.

DISPATCH & DELIVERY

We pack your goods carefully to avoid any damage.

First pioneer of

next-gen

manufacturing

NanoVoxel has been the first, and thus most experienced, company to respond to the customers' need for ultra high-precision microparts. Using our expertise and the most advanced technologies on the market, we have supported them on many challenging projects.

150+

PROJECTS

50+

CUSTOMERS

#1

STRATEGIC APPROACH

Why customers trust NanoVoxel?

Have you got a micro-challenge to solve?

Send us your request.

bottom of page

).png)